Add-On – Drilling, Reaming, Thread Cutting and much more

Various services combined in one product

On the way to the completed product, these smaller tasks are of extreme importance and are therefore combined in a separate segment called “Add-On”.

Whether you need thermal bending, hydraulic bending, drilling, thread cutting, or mounting of studs, KURIOS is the right place to be.

Surface refinements of any kind are part our range of services as well. These include tasks like polishing, brushing, grinding, sandblasting, glass bead blasting, and barrel finishing. We have been working closely with specialized companies in the surrounding area for many years. That enables us to offer you decorative and wear-resistant surfaces through powder coating or galvanic procedures.

Our entire team ensures optimized and smooth operations from consultancy and programming with latest CAD/CAM technology to the optimal result and its delivery.

If you want to be able to unconditionally rely on your service provider and feel in good hands at all times, KURIOS is the right place to be. At KURIOS you will get unlimited flexibility from a single source. Get in touch with us.

Add On – many different procedures

KURIOS offers various surface treatments

-

Surface refinement:

Sandblasting, glass bead blasting, grinding, brushing, satin finishing, barrel finishing, lacquering, galvanic procedures

-

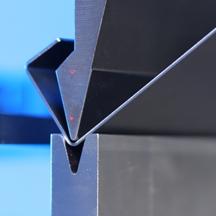

Hydraulic bending:

CNC-controlled bending; plastics up to a thickness of ca. 20 mm, sheet metal up to a thickness of 10 mm; bending radii from 1 mm

-

Thermal bending:

Up to 2000 mm width with top and bottom heat; cycle-controlled, automated sheet metal benders; special sheet metal benders for very sensitive and thin materials

-

Drilling:

Speed-controlled high-speed drill; thread cutting device; automatic thread cutting feed; thread tapping

-

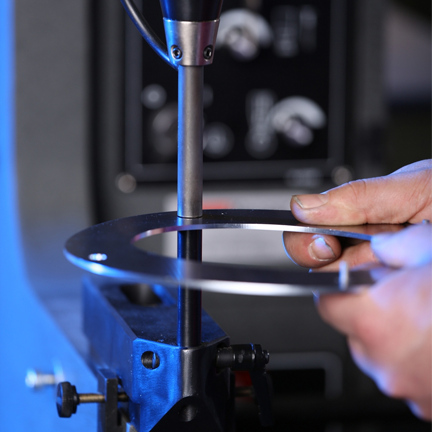

Stud welding:

Spot welding and stud welding with tip ignition; M3-M8

-

Self-clinching fasteners:

CNC press-in machine for threaded inserts, rivets, studs, threaded pins, nuts, and grounding prongs