HSC Milling High-Performance Plastics

High-speed machining of plastics from PEEK to PVDF

One of the first known high-performance plastics was PTFE of Teflon® – an invention of the aerospace industry. Nowadays, we have many different high-performance plastics whose specialized properties have been adjusted for the respective application purposes. PEEK, PPS, PVDF, and many others have become indispensible for modern industries over the past few years. These materials are way more efficient when it comes to high temperatures, wear and tear, or exposure to radiation.

Parameterization and the ideal process window play a decisive role when processing high-performance plastics.

Parameterization and the ideal process window play a decisive role when processing high-performance plastics.

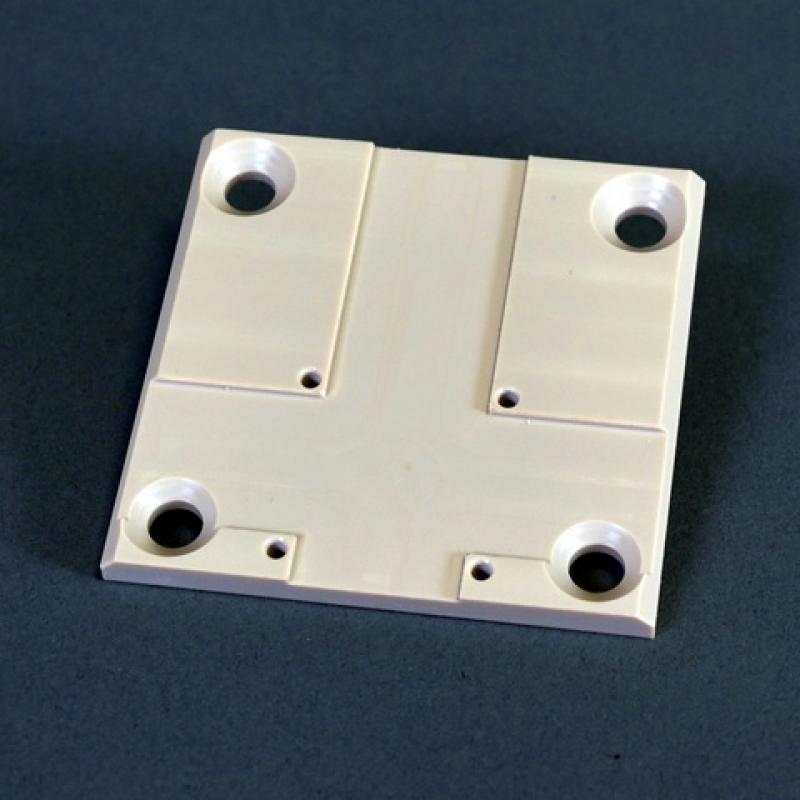

Each material needs individual optimization in terms of cutting speed, feed rate, cooling, and infeed. Without that, one would not be able to permanently meet high requirements in regards to tolerances, extreme precision, engineering fits, and high geometric dimensioning and tolerancing.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”.

So, if you are looking for a service provider to unconditionally rely on at any time, you have come to the right place. We would be more than happy to receive your request.

Quality assurance of your components is continuously happening throughout the entire manufacturing process and the records are stored in our ERP system “KISS”.

So, if you are looking for a service provider to unconditionally rely on at any time, you have come to the right place. We would be more than happy to receive your request.

High-performance plastics are used in all industries

High-temperature ranges, mechanical engineering, medical technology, aviation, aerospace, electrical engineering, chemical industry, food industry, nuclear industry.

Milled component made of PEEK plate material

Couplings made of CFRP PEEK

High-Performance Plastics

-

PEEK (Ketron®):

good mechanical properties, service temperature +240°C (+464°F), good stability at high temperatures, high radiation resistance

-

PAI (Torlon®)

maximum allowable service temperature at +250°C (482°F), good friction and wear behavior, high UV resistance

-

PPS (Techtron®)

very good mechanical properties, high permanent service temperature of +220°C (+428°F), good electrical insulation, excellent radiation resistance

-

PPSU, PSU, and PEI (Tecason®)

very good mechanical properties, good electrical insulation, approved to be used in food contact applications, suitable for steam sterilization

-

PTFE (Teflon®)

thermally stable from -220°C (-364°F) to +260°C (500°F), high chemical resistance, very low coefficient of friction, physiologically harmless

-

PVDF (Symalit®)

good antifrictional properties and wear resistance, good mechanical strength and rigidity, high toughness at low temperatures

HSC milling of high-performance plastics – important details summarized

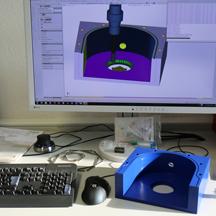

Processing of high-performance plastics takes place at KURIOS by means of cutting-edge multi-axis HSC milling systems and perfectly tuned process parameters. Furthermore, particularly critical materials need pretreatment as well as follow-up treatment to reduce internal stress, so that dimensional stability can be assured. Here, our years of experience and well-maintained knowledge database pay off. Our ERP system “KISS” perfectly supports us in this respect.

-

Maximum size:

2,000 mm x 3,000 mm

-

Minimum material thickness:

0.5 mm

-

Maximum material thickness:

100 mm

-

Machines:

Flatbed milling machines, portal milling systems

-

Further processing offer:

2D and 3D laser cutting, 5-axis simultaneous milling, laser welding, laser marking, turning, bending, and Heli-Coil

-

Surface refinements:

Lacquering, sandblasting, abrasive-blasting, grinding, and brushing

-

Thermal treatment:

Tempering in time and temperature-controlled heat cabinets