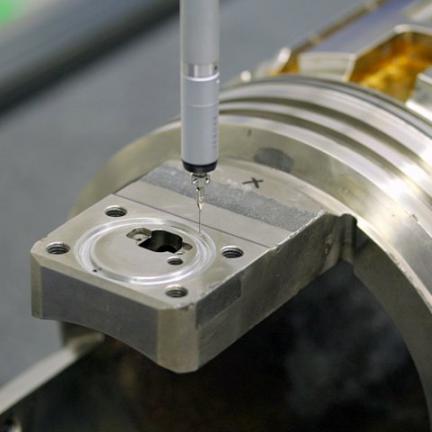

Laser Welding Tool Steel – precision and quality without compromises

Repair welding and cladding of tool steel

All common kinds of tool steel are welded with filler materials of the same kind or similar to it. That results in a homogeneous, sound joint, which has the same properties as the base material. Pulsed laser welding causes no structural transformation or change of hardened and tempered areas thanks to the small heat-affected zone. It allows you to use repaired tools without going through hardening and tempering procedures.

Our employees have the long-term experience, necessary know-how and manual skills to provide you with high-quality repair weldings. Benefit from our skilled team at KURIOS!

We are looking forward to your request regarding repair welding of tool steel. Get in touch with us now.

Repair welding of tool steel

Laser welding of tool steel – the key facts summarized

We guarantee perfectly crafted repair weldings. We will pare reworking (particularly of hard materials) down to the minimum, so that your part is ready for use in no time.

-

Maximum size:

1,000 mm x 1,000 mm

-

Minimum material thickness:

0.05 mm

-

Maximum material weight:

2,000 kg

-

Benefits:

No structural change of the base material, welding without warping, no hardening or softening, filler material of the same kind, high welding speed, pinpoint energy exposure, precise material application

-

Sections and tool steel:

1.2310, 1.2311, 1.2312

-

Highly alloyed tool steel:

1.2083, 1.2343

-

Usually weldable without pre-heating:

1.2379, 1.2767

-

Further processing offer:

Laser cutting, HSC milling, bending, laser marking, engraving, thread cutting, drilling, turning, thermal bending, and Heli-Coil

-

Surface refinements:

Lacquering, sandblasting, abrasive blasting, grinding, and brushing